How to Harden Sticky Resin – The Best Tips for Hardening Resin

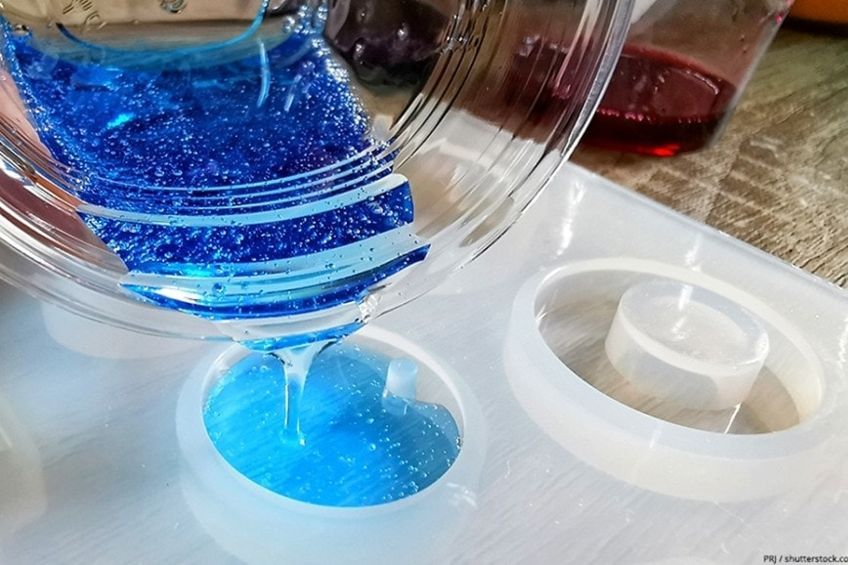

Epoxy resin has fast become one of the most used substances on the face of the planet. This comes as no surprise considering how versatile it is. It has been used in industries such as engineering, boat building, fine art, installation art, woodworking, interior decoration, and even in the design of smart devices. Not all resin products are the same though, some can be poorly made or simply trickier to use than others. This can result in some resin castings, and even resin surface coatings curing poorly or not at all, but what causes these imperfections in the curing process? Below we’ll be having a look at some circumstances that could lead to your resin not curing correctly and discuss how to fix resin that didn’t cure, as well as how to avoid these situations entirely.

Hardening Resin: What Causes It Not to Cure Properly?

There are many reasons why your resin may not have cured correctly, but typically this is because the mixture was poured or mixed incorrectly. Conventional epoxy resin is designed to be mixed in a perfect 1:1 ratio, which means that there should be exactly the same amount of resin and hardener in your mixing container before you stir them together.

If this ratio is grossly neglected, it will likely result in one of two things: either your resin will not catalyze correctly, or it will not cure completely (or it simply will not cure at all). This can result in a number of different imperfect finishes, of which most can be easily corrected or replaced. This being said, let’s have a look at a few possibilities and see what can be done about them.

| Type of Imperfection | What Causes It? | How to Remedy It |

| Runny Resin | Resin that has been made poorly or if your resin-to-hardener ratio is off. | Scrape off all of the runny resin. Ensure that your workpiece is completely clean before applying your replacement coating. |

| Sticky/Tacky Resin | Resin has been exposed to temperatures that are too cold or the environment is too humid. Can also result from an incorrect resin-to-hardener ratio. | Move your resin to an area where the temperature and/or humidity are conducive to the curing process. If the temperature is not an issue, simply apply another coat of resin over the stick resin surface. |

| Soft Spots | Typically caused by already cured pieces of resin that have become trapped in your workpiece during the curing process. | Sand the fully cured surfaces of the resin you have applied. Remove/ scrape out any soft spots. Clear off any resin dust. Apply a new coat on top of your existing one. |

Runny Liquid Resin

This is one of the most common imperfections when working with resin. Why does it happen? Well, it can happen if the resin or hardener you’re using has been manufactured poorly, but typically this happens when your mixing ratios are off. This happens most often when working with unconventional resin types like UV resin or deep pour resin.

These can be challenging to mix because of the volumes they’re used in, especially for beginners. It often results in resin that is not entirely set and can be even more challenging to correct because the volume of resin used is difficult to alter. Runny or sticky rein can also occur when too much coloring agent or cold temperatures are involved, which can throw off the thermic reaction needed to solidify the substance.

Soft or Sticky Spots

Soft or sticky spots on your resin workpiece are one of the more uncommon scenarios to encounter when you’re working with resin. You’re far more likely to have consistent imperfections across your workpiece due to mixing errors or unfavorable environmental conditions. What causes sticky spots across the surface of your workpiece if not these conditions? Sticky spots are typically formed due to the epoxy solution being contaminated in some way or another. The contaminant is commonly old, cured resin that has found its way into the resin you have used to create your workpiece.

This happens when mixing containers are not cleaned adequately, which can result in these already cured particles getting stuck in your workpiece. These particles prevent certain areas of your workpiece from curing.

Tacky or Sticky Resin

Does tacky epoxy ever cure? Tacky or sticky resin is a weird thing to come across, and can easily be dismissed as your resin simply needing a bit more time to cure. Why does this happen though? Much like when the resin is runny and will not cure, tacky or sticky resin is typically the result of an incorrect mixing ratio but can also be attributed to things like cold weather or excessive humidity during the curing process.

Thankfully, tacky or sticky resin is a lot easier to correct than some of the other scenarios you might come across, leaving you to remove the entire coat of resin and mix up another batch. Encountering this scenario is preferable to the one we mentioned previously and is the ideal situation to be faced with when you’re asking yourself, why is my resin not hardening?

How to Harden Sticky Resin

Wondering how to harden sticky resin surfaces? As we mentioned previously, there are a few situations you could find yourself in where you’ll find your epoxy not hardening. Epoxy not hardening is a weird thing problem to be stuck with, but statistically, you will encounter this issue on your crafting journey.

This being said, let’s have a look at some solutions to some of the sticky epoxy scenarios we have covered thus far.

How to Fix Runny Liquid Resin

As we mentioned previously, this scenario is usually caused by mixing your resin and hardener together in incorrect ratios. This will result in the resin being unable to catalyze and leaving you with a bit of runny mess. Since the thermic reaction cannot take place, there is no real way to remedy this situation by adding or removing an element of the resin. This leaves you with pretty much only one option, and that’s to start over from scratch. Does this suck? Absolutely, but if you’re quick and thorough about it shouldn’t take much effort or time for that matter.

How do you go about this? Well, for starters you can remove the runny resin from the surface of your workpiece. Ensure that you get all of the resin off the surface, or you won’t be able to do much with your workpiece. Once the resin has been removed, ensure that your surface is completely clean. This might require you to use a cloth to remove any residual epoxy trapped in grooves or corners depending on the size and shape of your workpiece. Once you’re sure that your workpiece is clear of all of the runny resin. Mix up a new batch (making sure that the ratio is correct this time) and apply it to your workpiece as you did previously.

How to Fix Sticky/Tacky Resin

Out of all of the scenarios you could encounter where your resin did not cure correctly, this is the one you should hope to encounter. Why? It’s one of the easiest to fix of course! If you’re wondering how to harden tacky epoxy you don’t have to worry about needing to remove all of the resin from your workpiece as you would with runny resin. Here’s how to harden tacky epoxy.

Since this is caused by environmental factors such as excessive exposure to cold temperatures and/or excess moisture in your immediate environment, all that you need to do is move your workpiece to an environment with an immediate atmosphere that is more conducive to the curing process.

Remember that the only reason that resin has a tacky or sticky finish is that it hasn’t been placed in an ideal environment, so you won’t need to worry about removing the resin or having to apply another layer. However, if you place your workpiece in a better setting and your resin still won’t cure correctly, you should add another layer of epoxy. So, does tacky epoxy ever cure? Yes, and surprisingly with little to no effort required by you.

How to Fix Soft Spots in Resin

Soft spots in resin aren’t the easiest to remedy, but they aren’t the most difficult either. As we mentioned previously, soft spots in resin are typically caused by contamination. This means that a foreign substance (usually old, dried bits of resin) has become lodged in your casting or surface coating as is therefore preventing your resin from curing correctly. Hardening resin that has failed to cure in this way can be a bit tricky. Since it’s not the entire surface but little spots that have failed to cure, you’ve going to have to tackle those areas individually instead of applying a blanket solution as you would if your resin was tacky or runny.

How do you go about hardening resin in these spots though? Well, it will require you to get creative and put in some elbow grease. First, sand down all of the fully cured parts of your workpiece with some medium grit sandpaper and ensure that it’s relatively uniform. Once you’re satisfied with the job you have done sanding, scrape out and remove all of the soft resin from the spots you have identified. Once you’ve done this, simply apply a fresh coat of resin over the surface of your workpiece.

How to Ensure That Your Resin Cures Correctly

Instead of wondering how to fix resin that didn’t cure correctly, let’s have a look at a few things you do to ensure that your resin cures correctly every time. Before we dive into that, always ensure that your workspace is well ventilated.

Ensure that you are wearing the appropriate personal protective gear when working with epoxy resin or any other materials that could cause potential harm to you or those around you.

Ensure That Your Workspace Is Conducive to the Curing Process

Regardless of which facet of crafting you find yourself in, the best thing to do before you start working on any project is to ensure that your workspace is adequately set up for the task ahead. When working with resin, ensure that the temperature and the airflow in your work area are within acceptable margins.

What you’re going for is a cross-flow of air in most cases, an entry and exit point to ensure that any fumes produced during the curing process are dissipated quickly. Next, assess the temperature in your work area and adjust it as needed using things like fans or space heaters to ensure that you get the best finish possible for your workpiece.

Clean Your Mixing Containers

Let’s face it, cleaning your tools and containers after crafting is nobody’s favorite chore, but it sure beats having to do your entire resin coating over from scratch. One of the most common causes of soft spots in resin is pieces of cured resin that have become trapped in the surface of a new casting. These cured pieces are often left-over resin from mixing cups that were improperly cleaned.

Cleaning your mixing sticks and measuring cups isn’t that hard either.

With the right solvents and some warm soapy water, you could clean all of your cups in just a couple of minutes. This can be difficult to convince yourself to do but if you make it part of your routine clean-up process it will definitely save you some time and money down the line.

Ensure That You Have the Correct Mixing Ratio

Most of the time resin doesn’t correctly cure because the ratio of resin to hardener is incorrect. This problem might seem easy to avoid, but when working with resin types like UV resin and deep pour resin it can get a bit tricky, especially if you’re looking to create resin in large volumes. A good way to avoid this issue is to invest in a decent set of mixing cups with measurement indicators on the outside.

It also helps not to make assumptions about the resin you’re working with. Do your best to check the limits that the resin you’re working with regarding the volume it can be poured in, as well as how long it takes to cure and what conditions it needs to cure correctly. Remember that it’s highly unlikely that you’ll know more about the product than those who made it.

Now that you know why resin doesn’t always cure correctly, some of the scenarios you might encounter when dealing with improperly cured resin, as well as how to deal with each of these respective scenarios, it’s time for you to get out there and put your new-found knowledge to the test. Remember to always work in a well-ventilated area and to always wear a face mask and some gloves when working with epoxy resin.

Frequently Asked Questions

How Long Should Epoxy Be Tacky?

How long should epoxy be tacky? Well, this really does depend on the type of resin you have been working with. If you have chosen to use conventional resin it should be completely cured within 24 hours after it has been poured. If it is still tacky after this, try placing your workpiece in a more suitable climate.

Why Is My Resin Not Hardening?

Why is my resin not hardening? Well, there are a few reasons this could be happening. If your ratio of resin to hardener is off, your resin will not harden. If the ambient temperature in your workspace isn’t ideal, or if your resin mixture has been contaminated, this could also cause your resin to not cure correctly.

Why Is My Resin Still Sticky?

Why is my resin still sticky? Sticky resin usually happens for one reason. When the area you’re working in is too hot, too cold, or too humid, this can cause the thermic reaction between your resin and hardener to fail or slow down. To remedy this, either move your workspace to a more suitable environment or alter the temperature of your current environment to suit the curing process.

In 2005, Charlene completed her Wellness Diplomas in Therapeutic Aromatherapy and Reflexology from the International School of Reflexology and Meridian Therapy. She worked for a company offering corporate wellness programs for a couple of years, before opening up her own therapy practice. It was in 2015 that a friend, who was a digital marketer, asked her to join her company as a content creator, and this is where she found her excitement for writing.

Since joining the content writing world, she has gained a lot of experience over the years writing on a diverse selection of topics, from beauty, health, wellness, travel, and more. Due to various circumstances, she had to close her therapy practice and is now a full-time freelance writer. Being a creative person, she could not pass up the opportunity to contribute to the Art in Context team, where is was in her element, writing about a variety of art and craft topics. Contributing articles for over three years now, her knowledge in this area has grown, and she has gotten to explore her creativity and improve her research and writing skills.

Charlene Lewis has been working for artincontext.org since the relaunch in 2020. She is an experienced writer and mainly focuses on the topics of color theory, painting and drawing.

Learn more about Charlene Lewis and the Art in Context Team.

Cite this Article

Charlene, Lewis, “How to Harden Sticky Resin – The Best Tips for Hardening Resin.” Art in Context. April 21, 2022. URL: https://artincontext.org/how-to-harden-sticky-resin/

Lewis, C. (2022, 21 April). How to Harden Sticky Resin – The Best Tips for Hardening Resin. Art in Context. https://artincontext.org/how-to-harden-sticky-resin/

Lewis, Charlene. “How to Harden Sticky Resin – The Best Tips for Hardening Resin.” Art in Context, April 21, 2022. https://artincontext.org/how-to-harden-sticky-resin/.